Until the end of the eighteenth century, ink-making was a normal part of the printer’s job, each printer making his own ink from the materials then available, and adding the colour, consistency, and other items which experience had taught to be required for each type of printing job.

Early inks used for printing did not vary much from those used by Gutenberg: finely ground pigment (lampblack for normal black ink) suspended in an oily medium (often linseed oil). Other ingredients might also be used such as resin, wax, or substances which increased the speed at which the ink dried.

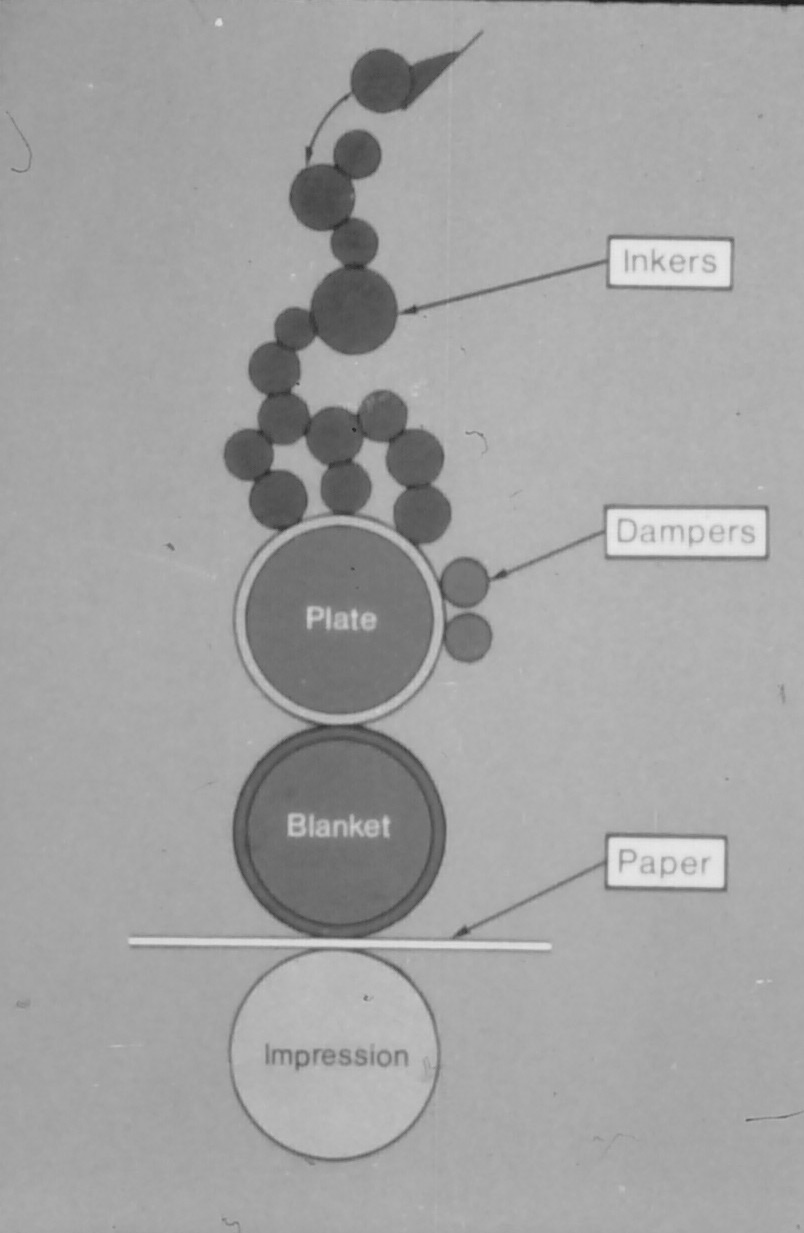

In the early years of printing the ink was distributed by hand using pads known as ink balls. A system of inking the forme with rollers was initially developed by Friedrich König (1774–1833) as an integral part of the cylinder press he developed in the early nineteenth century. The same principles have continued to apply for letterpress and litho machines ever since.

About 1800, the manufacture of ink began to develop into a separate industry.With the development of a wider range of printing processes, there was also a need for more varied printing inks, which are usually distinguished by the method of drying. Inks for letterpress and lithography dry by a combination of methods: evaporation, penetration into the paper, and oxidation. Photogravure inks, and all inks based on aniline dyes, dry entirely by evaporation. Newspaper inks are absorbed into the paper and dry very rapidly.

As modern web-fed rotary presses run at high speeds, inks have been developed that dry on contact with the paper, which reduces the risk of set off. Faster presses also led to new methods of distributing the ink onto the type using reservoirs and systems of rollers.

A B Fleming & Co were perhaps the best known of the Scottish ink manufacturers. The firm was established in the 1850s in Leith, later moving to Caroline Park in the Granton area, with additional premises in Corstorphine from the 1960s. At one time they also operated a factory in Dundee. The company ceased trading in the 1980s.

SPRAT is grateful for support from The Watson Foundation

SPRAT is grateful for support from The Watson Foundation