Iron presses could withstand greater force, which was exerted on the larger platen by a more powerful range of levers, and thus enabled the printing of larger sheets at a time. In the second half of the nineteenth century the original flat-bed press was developed into the modern sheet-fed flat-bed or platen presses. The flat bed was no longer necessarily horizontal, but might be sloping or even vertical. The sheets of paper are still held in place by tympan and frisket as in Gutenberg’s press, but on a steel slab, enabling greater pressure to be used. The forme and the surface to be printed are brought together for printing by mechanical action. Smaller presses were operated by hand, using a system of levers, and some larger ones by a treadle action, such as the Franklin press which originally made 1856.

An innovation of the early years of the 19th century was the use of a cylinder to carry the paper. Friedrich König was a pioneer in this field, developing cylinder presses for the Times in London from 1814. The three main types are ‘stop-cylinder’ in which the cylinder stops while the bed of the press, containing the forme, is returned; ‘two-revolution’ in which the cylinder continues to revolve, making one revolution to print as the forme moves forward, and another (in a raised position) while the forme returns; and ‘single revolution’ in which the cylinder also revolves at constant speed but only makes half a revolution for each movement of the bed.

An innovation of the early years of the 19th century was the use of a cylinder to carry the paper. Friedrich König was a pioneer in this field, developing cylinder presses for the Times in London from 1814. The three main types are ‘stop-cylinder’ in which the cylinder stops while the bed of the press, containing the forme, is returned; ‘two-revolution’ in which the cylinder continues to revolve, making one revolution to print as the forme moves forward, and another (in a raised position) while the forme returns; and ‘single revolution’ in which the cylinder also revolves at constant speed but only makes half a revolution for each movement of the bed.

Thomas Nelson, son of the founder of the Edinburgh firm, developed a rotary press which was demonstrated at the Great Exhibition of 1851. However, the machine was never patented, so its inventor did not benefit from the many versions which followed. The machine was fed by a web of paper, and the printing surface was formed by curved stereotype plates mounted on cylinders. The printed paper was passed under a serrated knife which cut the web into sheets. The original press was shown again at a trade fair in Leipzig, which led to it being impounded during the First World War (it was returned in 1919). It is now on show in the Museum of Scotland in Edinburgh. Newspaper presses were based on these principles for a hundred years.

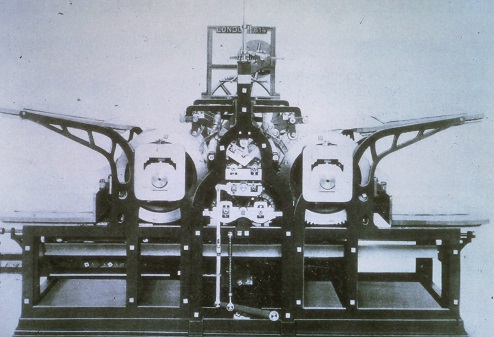

The Wharfedale press is a ‘stop-cylinder’ design, consisting of a travelling flat bed holding the forme of type, which was passed under inkers. The first one was made by William Dawson of Otley in Wharfedale, for the Glasgow firm of G W McLaren. The machine and its name were never registered, and many other firms have produced versions of the Wharfedale, and much updated models were still in production towards the end of the twentieth century.

The Miehle press originated in 1887, invented by Robert Miehle in Chicago, was a two-cylinder machine, which turned out to be especially appropriate for process work, and has been much developed since its first appearance. Other models have since been developed and exported widely. Later models have included vertical and two- revolution versions, and there are also models suitable for two-colour printing and high speed fully automatic models.

As printing machines became more complex a whole industry supplying machinery to the trade grew up. As a major centre of the printing trade, Edinburgh was also home to a number of these firms as well as firms supplying machines to allied trades such as paper makers. Well-known printing-press makers include Thomas Long and Patrick Ritchie.

The third edition of Kelly’s Directory of Stationers, Printers, etc, published in 1880, not only lists printers, publishers, bookbinders and stationers but also includes many companies making everything from ‘Bookbinders’ Thread’ to ‘Paper Making Machines’. Some of these firms were large operations and supplied printing firms throughout the world, including John Greig & Sons, of Fountain House and the paper makers’ engineers companies Bertrams of Sciennes and James Bertram & Son at the Leith Walk Foundry.

The third edition of Kelly’s Directory of Stationers, Printers, etc, published in 1880, not only lists printers, publishers, bookbinders and stationers but also includes many companies making everything from ‘Bookbinders’ Thread’ to ‘Paper Making Machines’. Some of these firms were large operations and supplied printing firms throughout the world, including John Greig & Sons, of Fountain House and the paper makers’ engineers companies Bertrams of Sciennes and James Bertram & Son at the Leith Walk Foundry.

Greig’s made presses for printers, bookbinders and lithographers, and their output included envelope making machines, copying presses and numerical printing machines. Other companies who were based near Greig’s in the Fountainbridge area of the city were Somerville & Crombie who also made presses for the printing and bookbinding trades, as well as papermaking machinery, Walker & King who supplied the papermaking industry from the Caledonian Engine Works in West Fountainbridge. Seggie & Co were based further east in Broughton Market.

SPRAT is grateful for support from The Watson Foundation

SPRAT is grateful for support from The Watson Foundation